Suntan Vacuum variable capacitor

Suntan Technology Company Limited

----All Kinds of Capacitors

A vacuum variable capacitor uses a high vacuum as the dielectric instead of air or other insulating material. This allows for a higher voltage rating and/or capacitance value using a smaller total volume. In addition to the higher voltage rating a vacuum dielectric greatly reduces the chance of arcing between the plates. There are several different designs in vacuum variables, the most common geometry of the capacitor plates is usually inter-meshed concentric cylinders. The meshed cylinders are contained within a glass or ceramic vacuum envelope, similar to an electron tube. A metal bellows is used to maintain a vacuum seal while allowing positional control for the moving parts of the capacitor.

Common Applications

Vacuum variable capacitors are commonly used in high voltage applications 5000 volts(5kV) and above. They are used in equipment such as high powered broadcast transmitters, Amateur radio RF Amplifiers and large Antenna tuners.

Other Variations

A fixed value vacuum capacitor. Other variations of vacuum capacitors include fixed value capacitors. Fixed value capacitors are designed very much like the variable versions with the exception of an adjustment mechanism.

Comparison

When compared to other variable capacitors vacuum variables tend to be more precise and more stable. This is due to the vacuum itself. Because of the sealed chamber the dielectric constant remains the same over a wider range of operating conditions. With air Variable capacitors the air moving around the plates may change the value slightly; often it’s not much but in some applications is enough to cause undesirable effects. Another common problem with air variables is dust and insects. Dust collected on the plates or a curious insect can raise havoc. A wandering spider is bound to make fireworks with the open frame design used on most air variable capacitors.

Vacuum variable capacitors are generally more expensive than Air Variable Capacitors this is primarily due to their design and the materials used. Although most use copper and glass some may use other materials such as ceramics and metals such as gold and silver. Vacuum variables also vary in adjustment mechanisms which range from course to fine.

Suntan is a Hong Kong based manufacturer of Ceramic Capacitors. Including High Voltage Ceramic Capacitors, Multilayer Ceramic Capacitors, Ceramic Disc Capacitor, Mini Type Ceramic Capacitors etc.

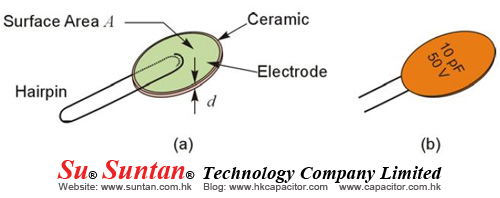

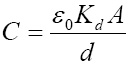

is the dielectric permittivity of vacuum, Kd is the dielectric's dielectric constant and d is the distance between the two plates.

is the dielectric permittivity of vacuum, Kd is the dielectric's dielectric constant and d is the distance between the two plates.