Suntan Technology Company Limited

----All Kinds of Capacitors

MLC capacitors are marvels of modern material science. Manufacturing MLC capacitors is considerably more complicated than manufacturing dipped ceramic capacitors. First, the base ceramic material is mixed with a binder and fashioned into thin sheets. Electrodes are painted onto one side of the sheets using a paint that consists of a liquid binder with fine metal particles in suspension. The metals that are used include gold, palladium, platinum, and silver alloys. The reason for using these metals is that when the base ceramic is fired, oxygen is required for the ceramic proper to form. If one uses a metal such as iron, for example, it would oxidize completely during the firing process.Precious metals do not have this problem, but is a major cost component of monolithic ceramic capacitors. However, recently some manufacturers have reported using nickel and copper for the electrodes. This promises to reduce the cost of the raw materials, but at the expense of more elaborate manufacturing processes.

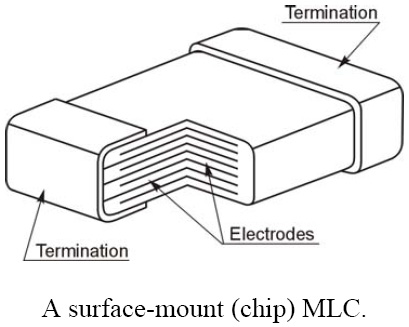

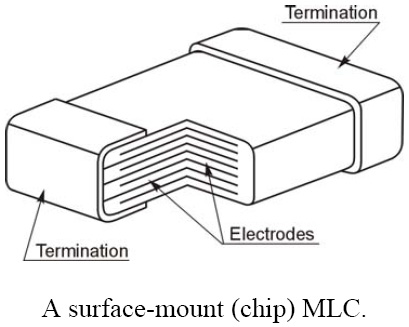

Once the ink is dry, the sheets are stacked on top of each other. The painted electrodes are arranged so that alternate electrodes exit from opposite ends. The top and bottom most layers do not have painted electrodes. The laminated layers are then compressed and fired, which sinters them into one monolithic structure.

Next, the ends are terminated, often using silver. For leaded capacitors, wires are attached, and finally the capacitor is encapsulated in plastic and marked. In the case of chip capacitors, the silver end terminations are covered with tin to aid soldering. The whole capacitor may be covered with lacquer.